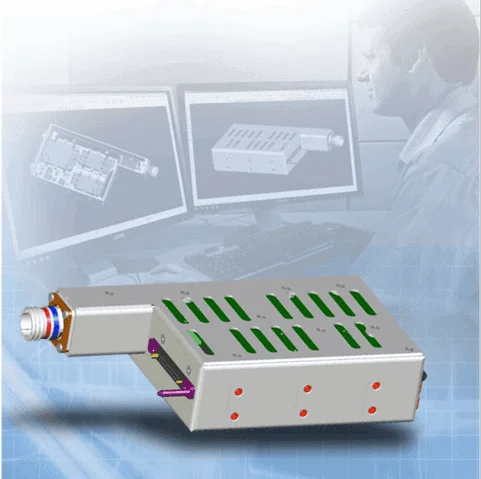

Ruggedized, Custom Power Supply Design and Manufacture

Corporate Overview

- A Veteran-owned Small Business

- Started in 1986

- Specializing in the design & manufacture of rugged electronics for military and industrial applications

- Power bricks, supplies and systems

- Embedded processor applications

- SCADA systems over cellular network

- A network of small businesses and independent contractors who come together on a project basis

- Engineering Team

- From 5W to 30KW, AC and DC for worldwide application

- Over 200 man-years of design experience

Value Proposition

- Power is our core competency

- Breadth of capabilities

- On-shore manufacturing

- Experience with mission critical DX programs

- ITAR compliant

- Field proven power components

- Saving valuable engineering time

- Risk mitigation

- Reduce cost

- Improve time to market

General Capabilities

- Electrical & mechanical design

- 3D modeling

- Solid model printing

- Thermal & electrical analysis

- MIL-STD compliance & certification

- EMI

- Input transients

- Environmental

- Qualification / life testing

- Manufacturing

- Rapid prototyping

- Environmental stress screening

- Failure analysis

- Program management

Design Simulation Analysis

- Thermal

- Mechanical

- Electrical

Thermal Analysis

- Thermal Simulation to locate potential problem areas

Mechanical Analysis

- Finite Element Analysis (FEA) to identify potential problem areas

- 3D mechanical models supplements the 3D CAD analysis

and provides insight to potential problem areas and allow

the end user to actually hold the concept - 10″ x 10″ x 12″ capability

Electrical Analysis

- Standard electrical simulation tools and schematic

- capture

- PSpice

- OrCAD

- PADS

- End-user typically defines and performs qualification which may include:

- Temperature cycle

- Temperature Humidity Bias (THB)

- Thermal Shock

- Vibration

- Humidity

- EMI

- First Article Inspection

MIL-STD EMI

- Use standard modules and proven circuits to minimize design and test time

- Use of local outside test facilities for certification and validation, if

required

Design Process

Design Validation

- Test design to contract performance requirements as agreed to by customer

- Thermal

- Mechanical

- Electrical

Manufacturing

Using Contract Manufacturers

- Purchasing

- Rapid Prototyping

- Production

Programs

- Fixed and rotary wing aircraft

- Gunfire

- High altitude and vacuum

- Surface ships and submarines

- Including 300G barge test

- Tracked and wheeled vehicles

- Manned and un-manned vehicles

- Factory floor, including Class 1, Div 2

- Hybrid vehicles

- Railroad locomotive

Get In Touch

Contact us to see how we can help meet your technical product requirements!